Used Twin Monkeys Beverage System Cimarron 10 head dual lane Canning Line

Used Twin Monkeys Beverage System Cimarron 10 head dual lane Canning Line

Location:Portland, OR

Available quantity:1

Description

Used Twin Monkeys Beverage Systems Cimarron dual lane 10 head filler/seamer. Set up to run with the SKA depal (item 8636) and the Pur-rinse rinser (Item 8637). The Twin Monkeys Cimarron is a higher speed can lien with dual lanes and 10 fill heads. It is designed to handle slim, sleek and standard can sizes with quick changover.

A Twin Monkeys Cimarron dual lane 10-head filler is a high-speed, automated, and customizable canning machine for craft beverages, designed for scalability from 1 to 10 fill heads and single to dual lane configurations. It handles various can sizes, achieves a throughput of 10-100+ cans per minute, and includes features like automated tank pressure control, CO2 purging, and liquid nitrogen dosing for oxygen reduction and precise fills.

Key Characteristics:

- Scalability: Starts as a single lane and can expand to a dual lane with up to 10 fill heads, allowing it to grow with a business.

- Speed: Capable of filling and seaming 10 to 100+ cans per minute.

- Customization: Highly configurable to meet specific craft beverage business needs, including options for different can heights and diameters.

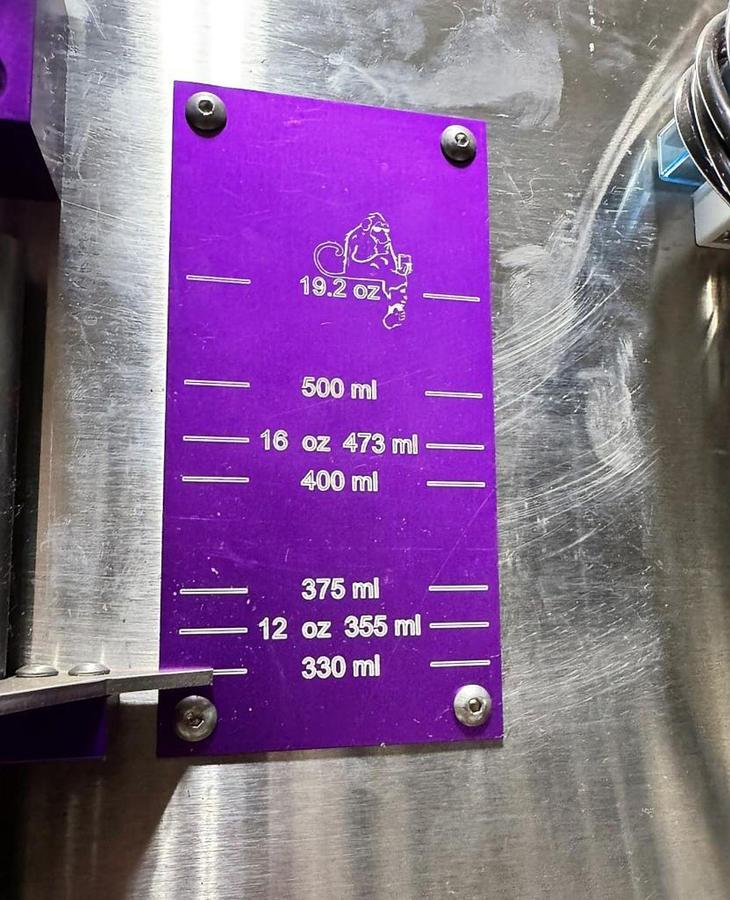

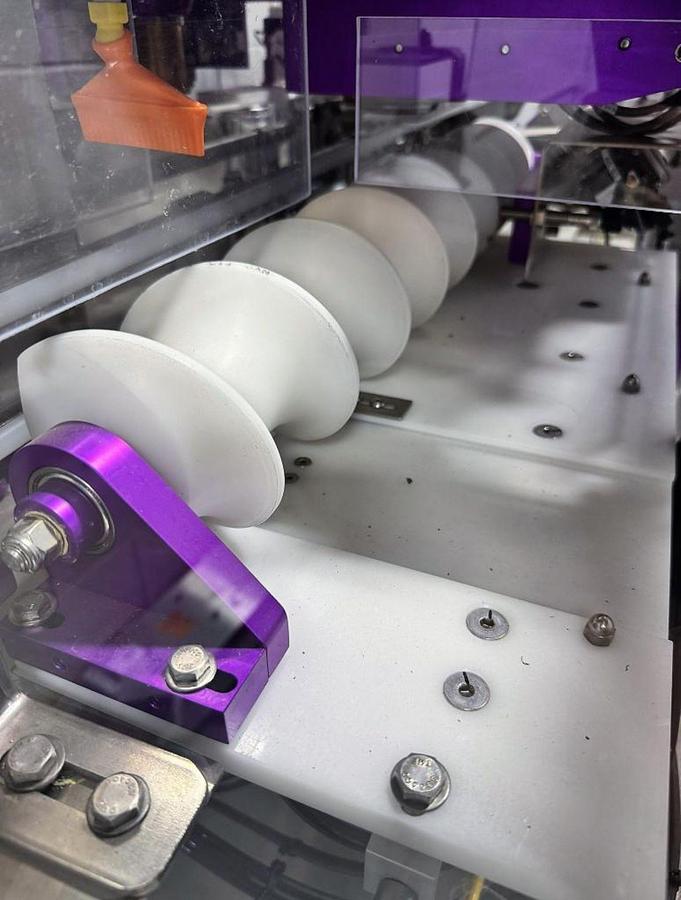

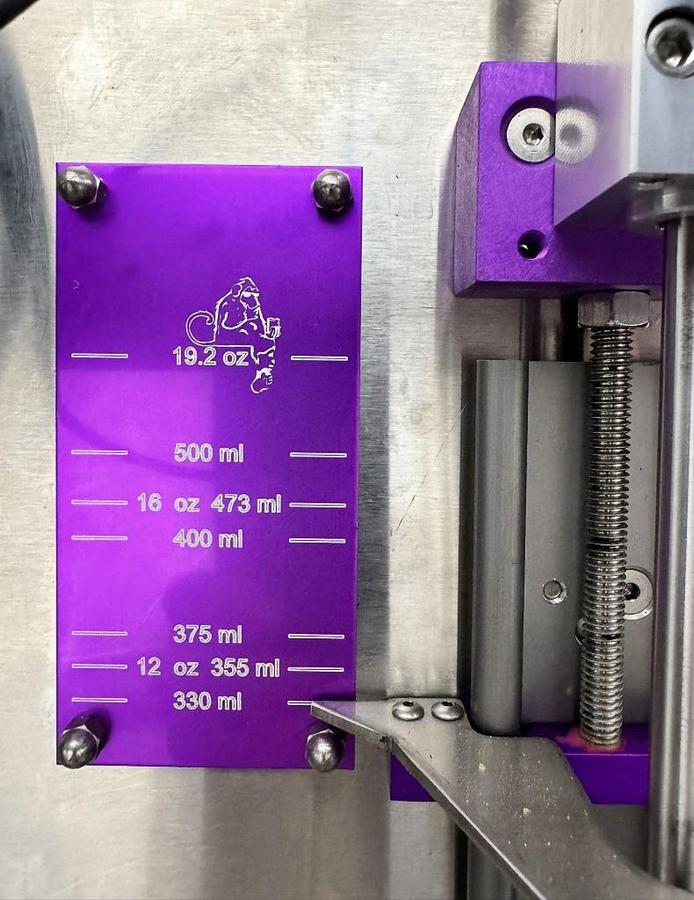

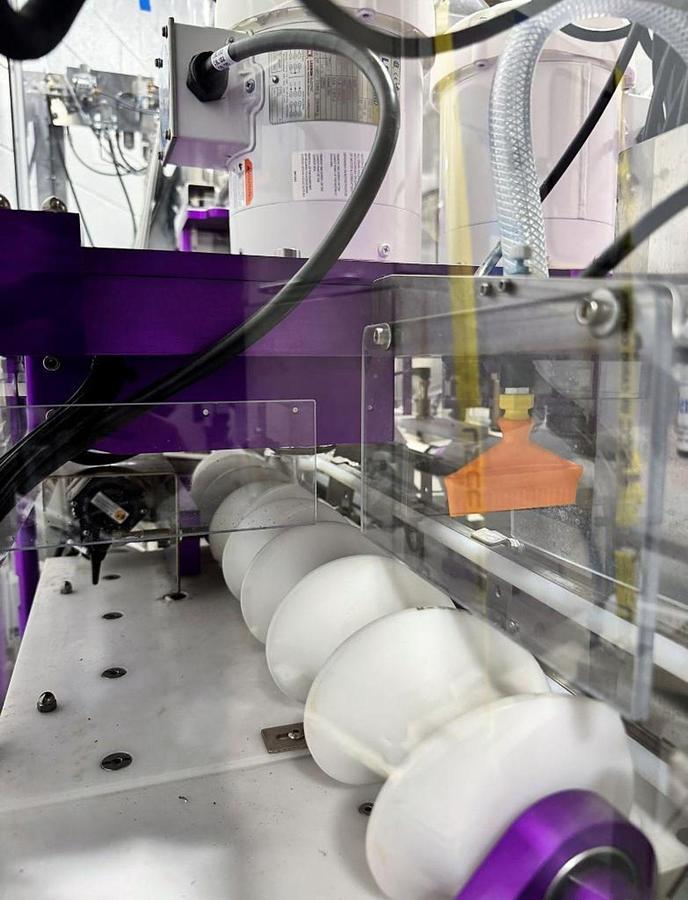

- Handling: Can process slim, sleek, and standard can sizes, with easy changeovers between sizes.

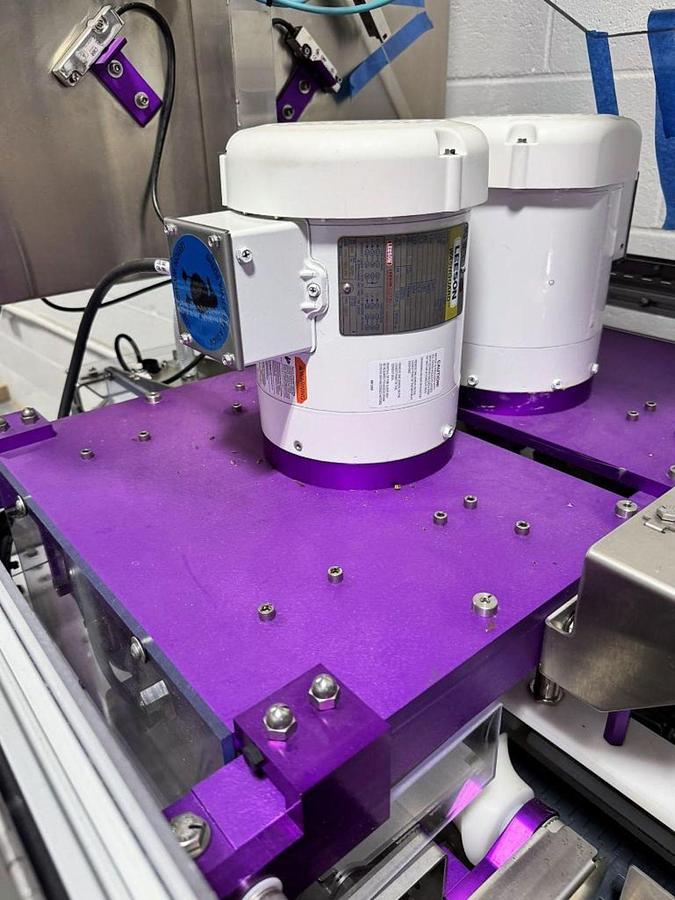

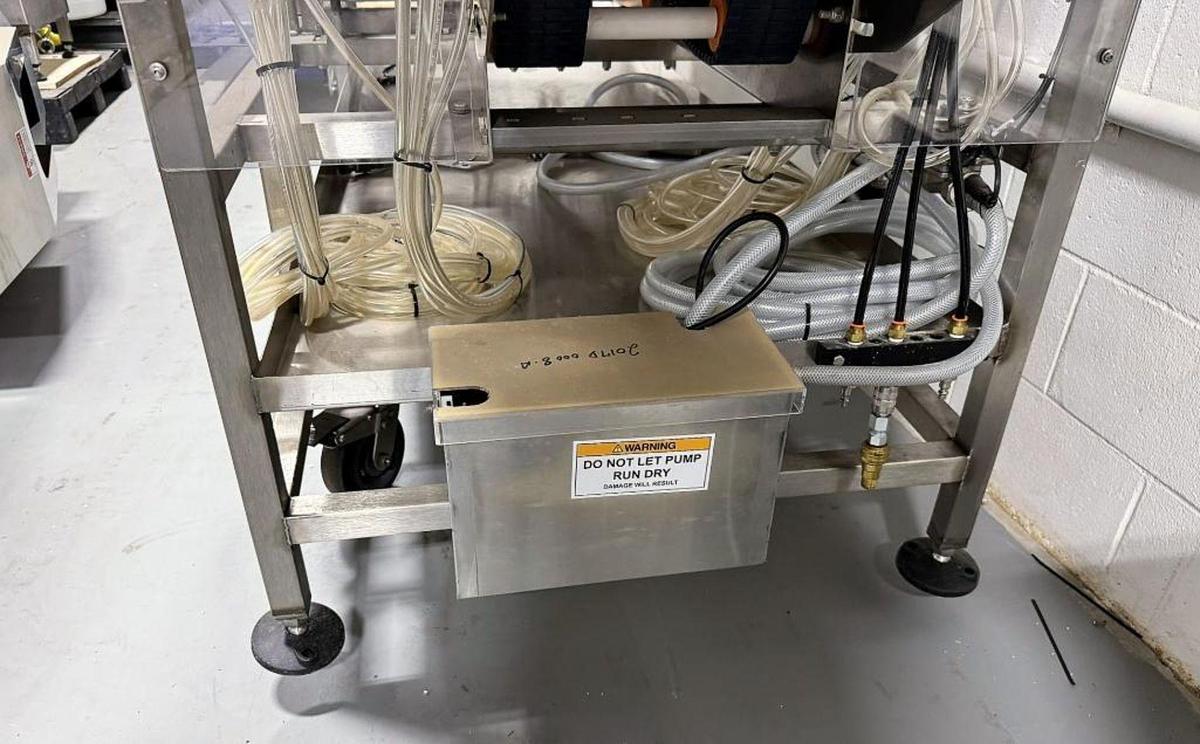

- Automation: Features automated brite tank pressure control, lid dispensing, and a fobber for foam creation to reduce oxygen.

- Oxygen Reduction: Includes advanced features like liquid nitrogen dosing and servo-controlled fill heads for minimizing oxygen exposure and maintaining beverage freshness.

- Footprint: Considered a robust yet compact machine, suitable for breweries with limited space, including mobile canning operations.

How it Works:

- CO2 Pre-Purge: The cans are first purged with CO2 to displace oxygen before filling.

- Filling: A pre-fill manifold distributes the beverage from a brite tank, while servo-controlled fill heads ensure accurate and consistent filling.

- Fobbing & Dosing: An automated fobber creates foam for oxygen reduction, and a liquid nitrogen doser can be integrated for even more precise oxygen control.

- Lid Application & Seaming: An automated lid dispenser applies can ends, followed by a servo-controlled, patent-pending industrial seamer station to create the seal.

- Quality Control: Cans are weighed post-seam, and any that are under the set weight are automatically rejected.

This machine was removed from service recently and is available for shipment immediatley. It can be mated to the following

8626 SKA depalletizer

8637 Pur-Rinse air rinser can cleaner

8639 MCE Accum Table

8640 Pack Leader Sleeve Labeler

8641 Pack Leader heat tunnel

8642 Twin Monkey 60" accumulation disc

Specifications

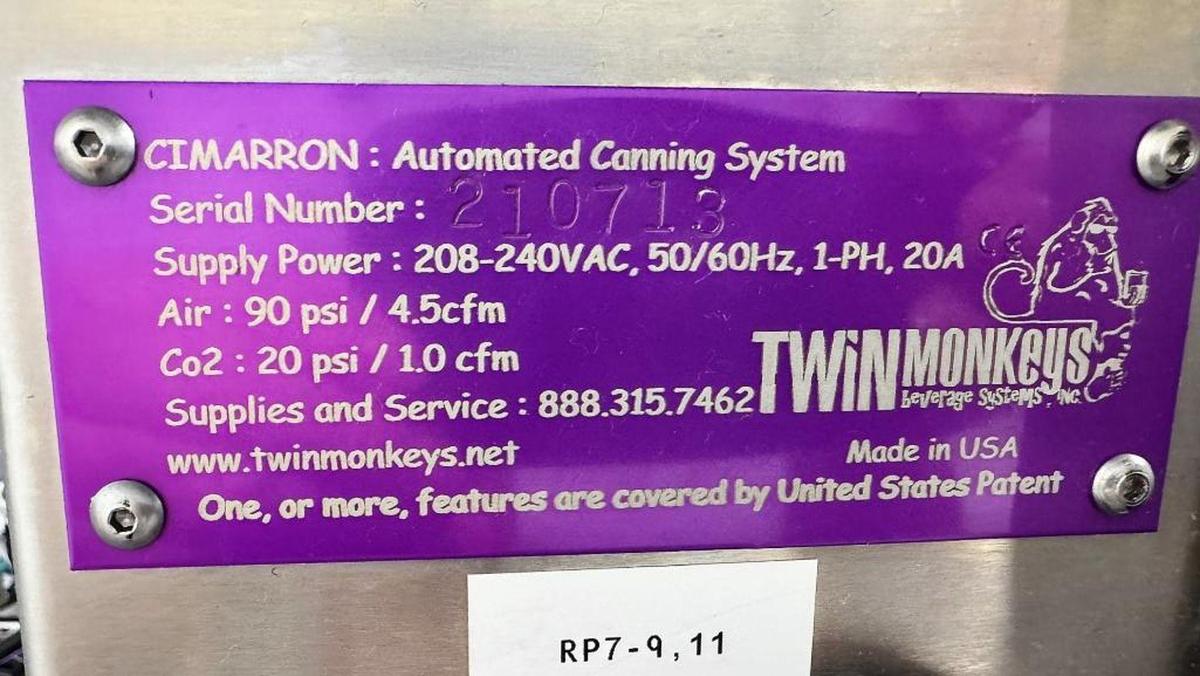

| Manufacturer | Twin Monkeys Beverage Systems |

| Model | Cimarron 10 Head |

| Year | 2021 |

| Condition | Used |

| Serial Number | 210713 |

| Stock Number | 8638 |